View Large

View LargeThe fuel filter may be the main filter or a secondary filter, a cylinder filter or a filter, a spin filter, a tank filter, or an inline filter. As we have seen, design and installation styles depend on several factors, including the car type, model, and year of manufacture. The same is true for the type of fuel system.

The new car’s fuel filters are different in design and location from their predecessors. Older petrochemicals have filters everywhere in the fuel line, while most modern cars have filters in the tank.

Fuel filters on diesel engines look and function differently from gasoline cars. Diesel filters are large, mostly bowl-shaped, and depending on the fuel system used, vehicles can use either the main filter or a secondary filter at the same time.

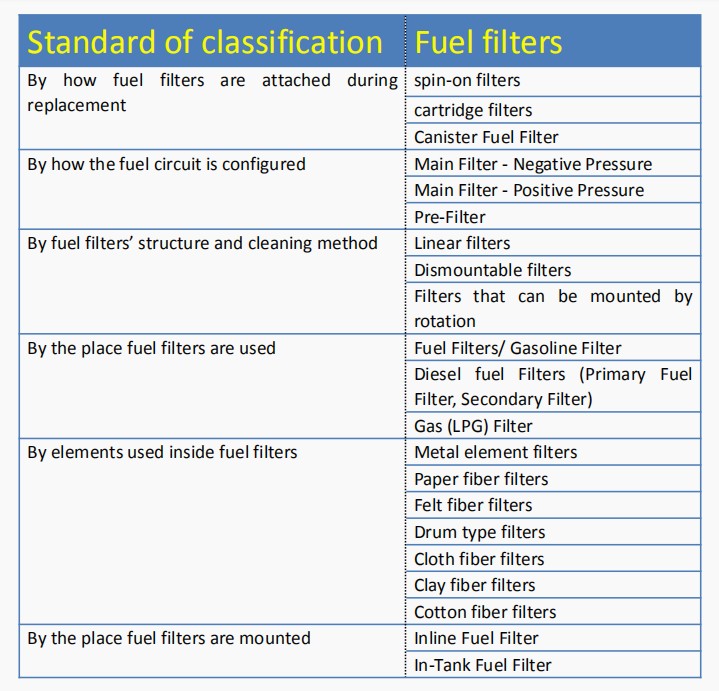

Classified by how fuel filters are attached during replacement

1. Spin-on Fuel Filters

The spin-on is installed on the vehicle using threads. The filter medium is contained in a metal case with threads at the bottom. The spin-on fuel filter is usually installed in the engine compartment. Their chief advantage is that they are easy to be replaced. This type provides excellent working ability as the whole case can be replaced. This process involves only undoing the damaged filter and fastening a new filter in its position. Except that the process only takes a short time, almost all car owners can complete it.

2. Cartridge Fuel Filters

This form of the fuel filter is characterized by a cartridge consisting of a filter medium, structural components, and other necessary fuel filter components. The only thing missing from these filters is the casing. Instead of a metal or plastic casing as part of the filter, it is a separate component mounted on the mating surface of the vehicle. It can be used over and over again, only the ink cartridge is a disposable part. Only the filter medium is changed, so this helps to reduce the amount of waste produced with each change.

The cartridge fuel filter is an environmentally-friendly choice. Since less metal or plastic parts are discarded, replacing the filter will have less impact on the environment. This means that, in contrast to the canister type of filter, components must be manufactured and thrown away to replace a failed filter.

3. Canister Fuel Filter

This is a filter characterized by a canister with a filtration element. Most filters are of this type. The housing can be plastic or metal, depending on several factors. Canister fuel filters are said to be less environmentally friendly. At the end of their life, the entire device needs to be removed and thrown away.

Spin-on Fuel Filters

Cartridge Fuel Filters

Canister Fuel Filter

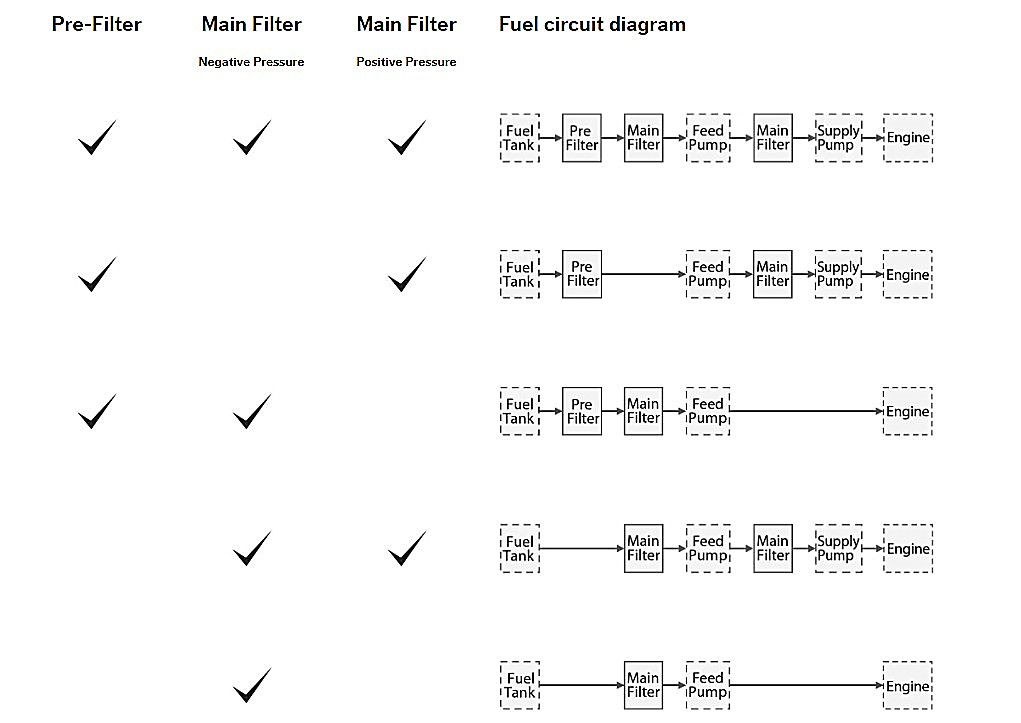

Classified by how the fuel circuit is configured

- Main Filter – Negative Pressure

The main filter is mainly responsible for catching fine pollutants. The negative pressure type utilizes the suction pressure generated by the feed pump and is closer to the fuel tank than the feed pump.

- Main Filter – Positive Pressure

The positive pressure filter takes advantage of the upward thrust pressure from the feed pump and is located closer to the engine than the feed pump. Some vehicles can be equipped with both negative pressure and positive pressure main filters.

- Pre-Filter

The pre-filter removes relatively large amounts of contaminants and water from the fuel. These are installed on the circuit, near the fuel tank.

Different types of filters are used depending on the model and engine. Typical examples as below:

Classified by fuel filter’s structure and cleaning method

Linear Fuel Filters

Dismountable Fuel Filters

Fuel Filters mounted by rotation

1. Linear Fuel Filters

A linear fuel filter is used in carburetors and jet vehicles. The outer coating is metal, and the inner filtration is composed of paper folds. Some other shells can be made of plastic. This type of filter is characterized by very large filter surfaces, and these are especially used in gasoline engines. In modern diesel engines, the filtering portion of the filter is made from high-pressure resistant paper folds. Because their surfaces are much larger, they ensure more efficient filtration, and they retain their absorptive capacity even after long periods of use.

2. Dismountable Fuel Filters

Dismountable Fuel Filters/Demountable Fuel Filter are mainly used for construction equipment. At the end of the service life, keep the external (metal) parts, and replace the internal parts. The advantage of this type of filter is that it is cheap and easy to replace. However, during these replacement processes, there is a risk of dust entering the fuel system.

3. Fuel Filters that can be mounted by rotation

Fuel Filters that can be mounted by rotation. Their structure is similar to that of oil filters, but these filters are fixed with a screw to minimize installation time. The used filter can be removed and a new filter can be installed immediately. This type of filter usually also has a water separation camera.

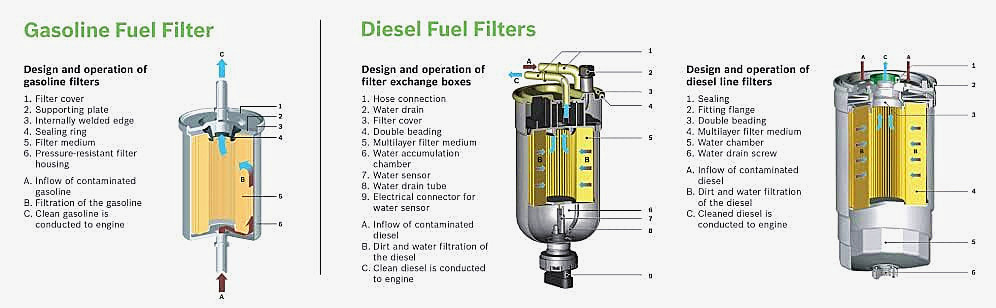

Classified bythe place fuel filters are used

1. Gasoline Fuel Filter

A wire or paper filter is used in the gasoline fuel filter. The wire filter is installed on the gasoline inlet of the tank, gasoline pump and carburetor. The paper filter is placed between the gasoline pump and the carburetor. This filter is also used in gasoline injection systems.

Fuel filters are not complex devices. They have only a few components. The gasoline filter can be said to be the most basic fuel filter. As they usually have no mechanism for extracting water from fuel, the structure is less complex. Gasoline systems usually rely on a filter. Gasoline is a cleaner fuel than diesel, and that’s why gasoline filter doesn’t need double filtration.

Gasoline Fuel Filter

Diesel Fuel Filters

Gas (LPG) Fuel Filter

2. Diesel Fuel Filters

In diesel motors, cartridge type filters are used generally. In the production of these filters; cotton yarn, low twisted cotton yarn, accordion shape pleated paper, cellulose disks, bags are woven with wool yarn, and densely knit filter bags are used. In order to clean the diesel fuel, a very good filter is placed to the inlet of the high-pressure pump, first. Also, it might be necessary to place filters between the tank and the machine or between the transmission pump and high-pressure pump or in both positions.

Diesel oil naturally contains more impurities, especially water and excess wax. To make diesel easier to use, manufacturers usually install a primary filter to remove particles, water, and wax, and a secondary filter to catch the remaining contaminants. It can also be a single filter with a mechanism to remove water and cause it to settle into a bowl inside the filter housing.

Some fuel systems use both primary and secondary filters to clean fuel entering the engine. Others use only one fuel filter, the main filter that removes particles, sediment, wax, and water from the fuel. Still, some systems use regular filters and additional water separators.

Primary Fuel Filter

Secondary Fuel Filter

- Primary Fuel Filter

This type of fuel filter is commonly used in diesel fuel systems. Its job is to filter out most pollutants including large particles, especially water and wax. The main filter is located on the vacuum side of the fuel pump. The primary filter usually has fewer restrictions. Because it usually does not need to catch finer impurities before the secondary filters in the fuel system. These filters mainly filter for particles larger than 10 microns.

- Secondary Fuel Filter

Secondary fuel filters are also used for diesel filtering to block finer particles smaller than 10 microns, and to remove water from the fuel. Therefore, the secondary filter is equipped with a tighter medium or medium with a high micron scale. In terms of location, these filters are installed on the pressure side of the fuel pump, which is usually close to the engine.

3. Gas (LPG) Fuel Filter

Gas (LPG) Filter is a kind of fuel filter that has been used in recent years with the increase of LPG vehicles.

Classified by elements used inside fuel filers

- Metal element filters

- Paper fiber filters

- Felt fiber filters

- Drum type filters

- Cloth fiber filters

- Clay fiber filters

- Cotton fiber filters

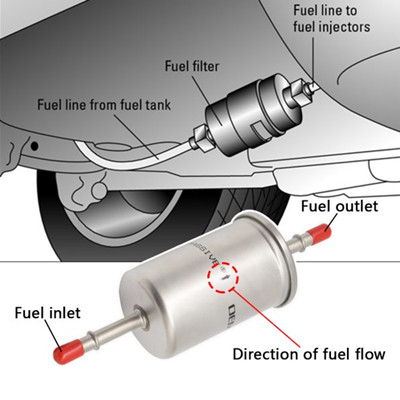

Classified by the place fuel filters are mounted

- Inline Fuel Filter

Inline fuel filters are installed on the fuel line, between the gas tank and the engine, underneath the vehicle. The filter has an inlet on one side of the fuel pump and an outlet on the other side. The two openings are connected to a hose or pipe constituting the fuel line and the device is held in place by a metal bracket and a plastic safety clip.

- In-Tank Fuel Filter

In-tank fuel filters are mounted in the tank, away from view. Most modern cars use a in-tank fuel filter. The filter can be individually separated or integrated into the fuel pump. One disadvantage of these types of filters is that they are not accessible, which makes them difficult to serve. When part of the fuel pump assembly, the in-tank fuel fuel filter cannot be replaced separately. This means that when you have to replace a clogged or damaged filter, it costs more money.